Business

Digital Factory

Digital Transformation 전략

기업 생존을 위한 Digital Transformation 전략 → 디지털 트윈 실현

가트너 선정 10대 미래 핵심 기술

2021년 대기업의 50%이상이 프로젝트에서 디지털 트윈 기술 활용

디지털 뉴딜의 디지털 트윈 예산: 1조 8천억

Digital Twin Solution

전문가뿐만 아니라 초보자도 활용 가능한 솔루션

파워포인트, 엑셀 등의 범용 소프트웨어 사용자라면 누구나 사용 가능

게임 하듯 디지털 트윈을 만들 수 있음

| 구분 | 항목 | 효과(%) | 설명 |

|---|---|---|---|

| 직접 | 생산성 향상 | 10 ~ 30 | 공장 운영에 대한 모니터링과 데이터 분석을 통해 생산성 저해요소를 실시간으로 파악하고 해결 개선활동을 통하여 지속적으로 생산성 향상에 대한 관리가 가능 |

| 설비 비가동 감소 | 20 ~ 30 | 설비 운영 현황에 대한 모니터링과 데이터 분석을 통해 설비 비가동에 대한 예측과 비가동 발생 시 즉시 해결할 수 있어 설비 비가동 수와 시간이 감소 |

|

| 생산비용 절감 | 10 ~ 20 | 설비의 효율적인 운영과 불량 및 비가동 요소를 실시간 모니터링하고 최적화 | |

| 간접 | 에너지비용 절감 | 10 ~ 20 | 공장 전체 및 라인, 설비 별 에너지 소요 및 손실 모니터링을 통해 에너지 비용 절감 |

| 품질불량 감소 | 10 ~ 20 | 품질 불량 최소화를 위한 활동과 예측 정보를 실시간으로 모니터링하여 불량을 사전에 예방 | |

| 품질비용 절감 | 10 ~ 20 | 품질 불량 감소와 비용에 대한 실시간 모니터링과 분석을 통한 비용 절감 | |

| 재고비용 감소 | 20 ~ 30 | 안전 재고 운영에 대한 실시간 모니터링으로 적정 재고에 대한 개선활동을 전개 | |

| 수불비용 절감 | 10 ~ 20 | 공정별 입출고 및 물류를 위한 작업 내용과 비용에 대한 모니터링과 데이터 분석을 통한 물류 비용 절감 |

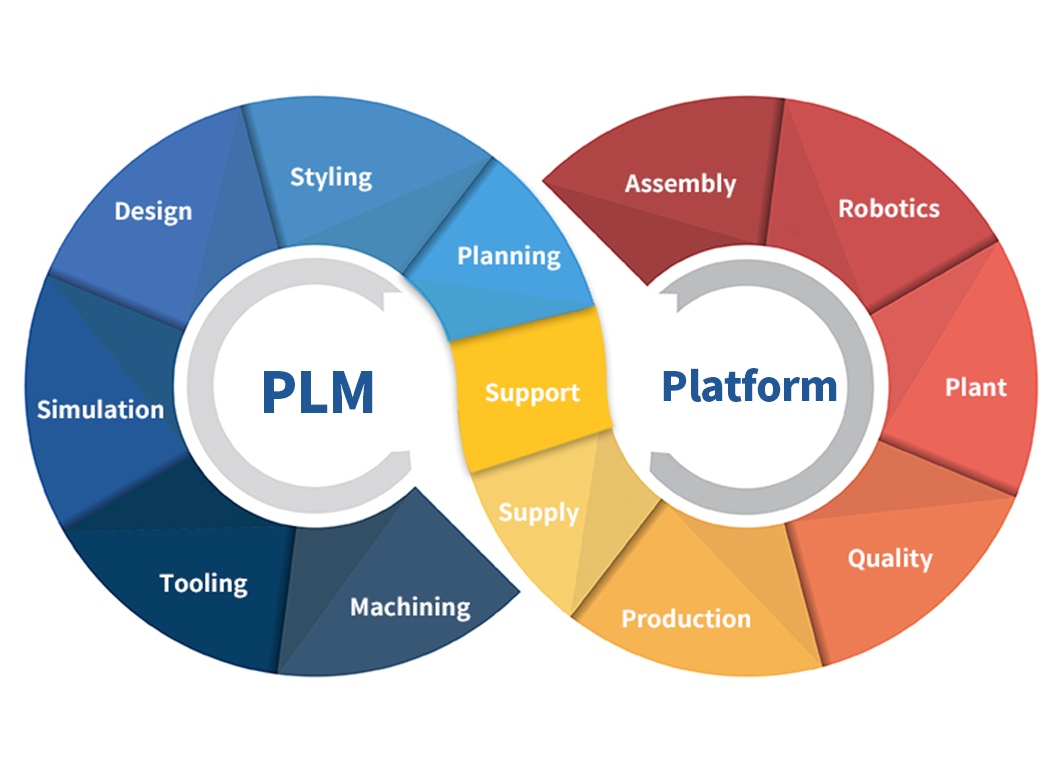

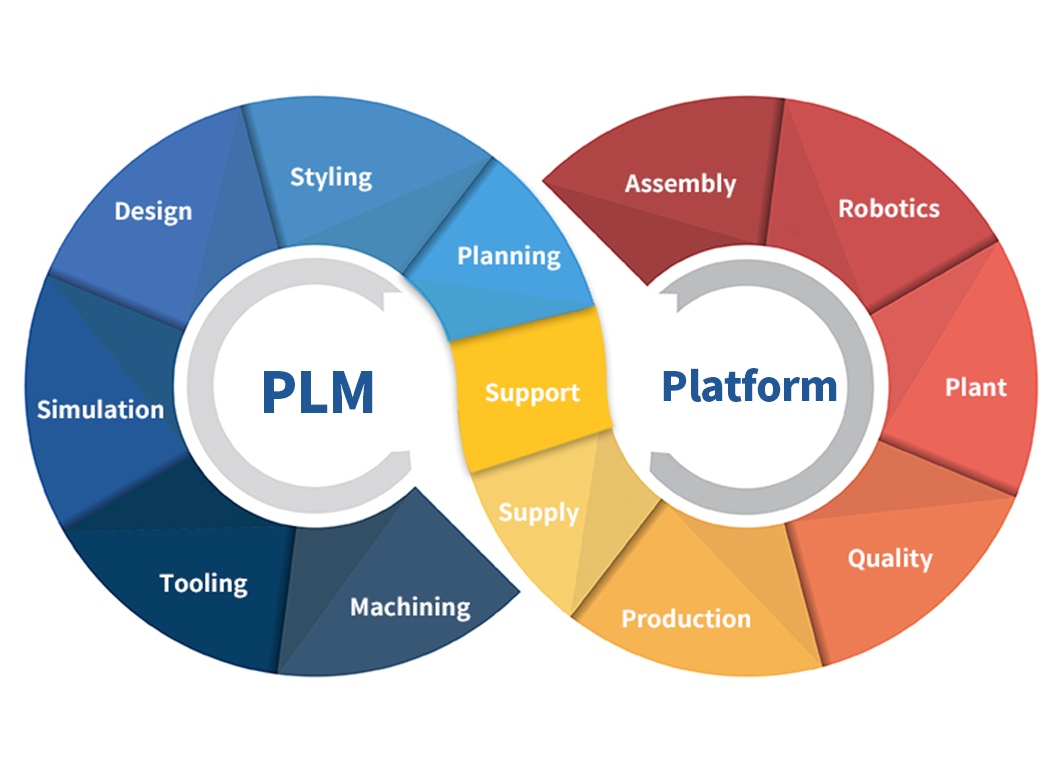

PLM(Teamcenter)

PLM provides a system that manages a product life cycle

by integrating all relevant information from the basic concepts

of the product produced by the manufacturer to design and

manufacture, post-service and disposal.

by integrating all relevant information from the basic concepts

of the product produced by the manufacturer to design and

manufacture, post-service and disposal.

PLM provides a system that manages a product life

cycle by integrating all relevant information from

the basic concepts of the product produced by the

manufacturer to design and manufacture, post-service and disposal.

cycle by integrating all relevant information from

the basic concepts of the product produced by the

manufacturer to design and manufacture, post-service and disposal.

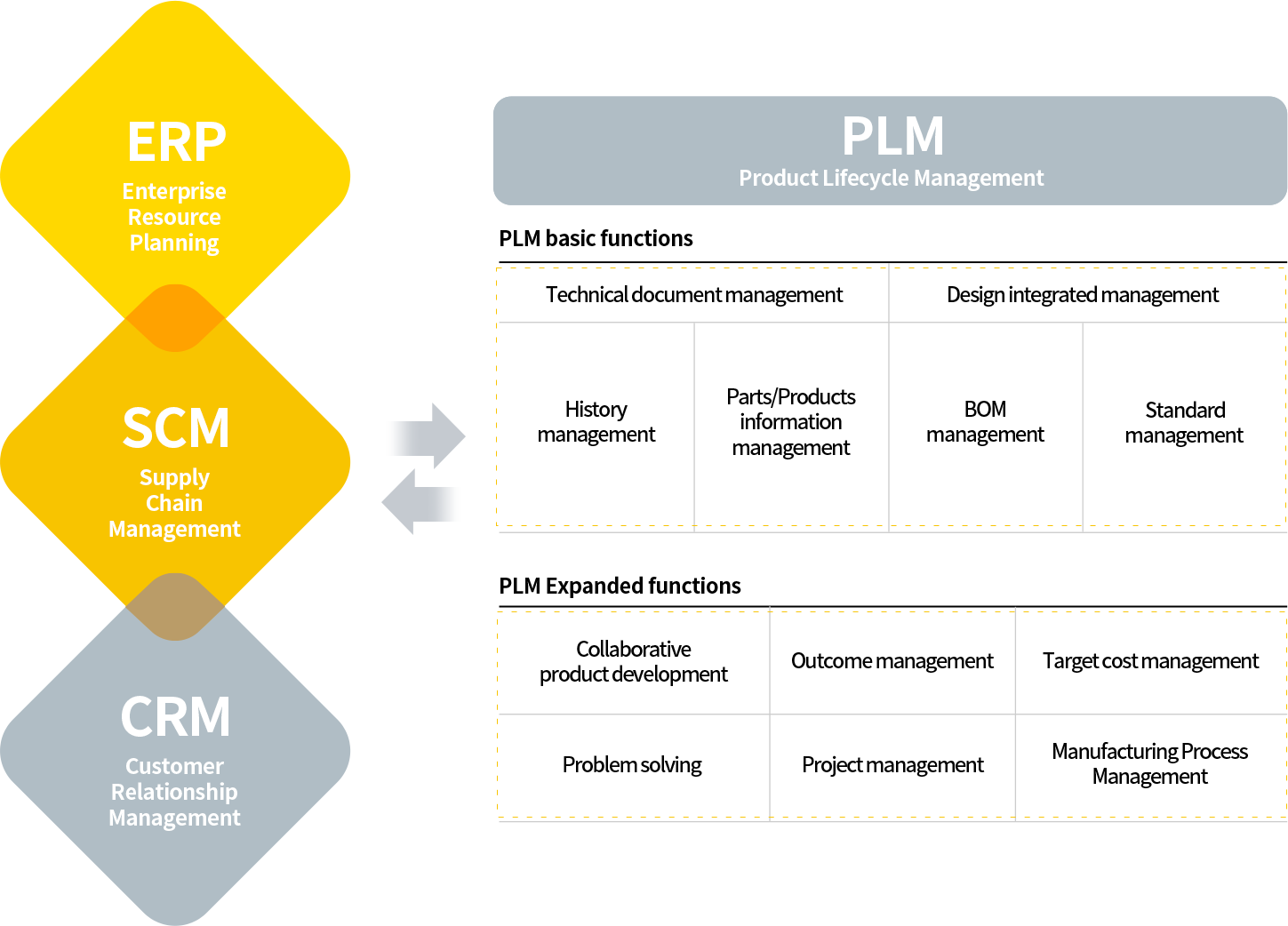

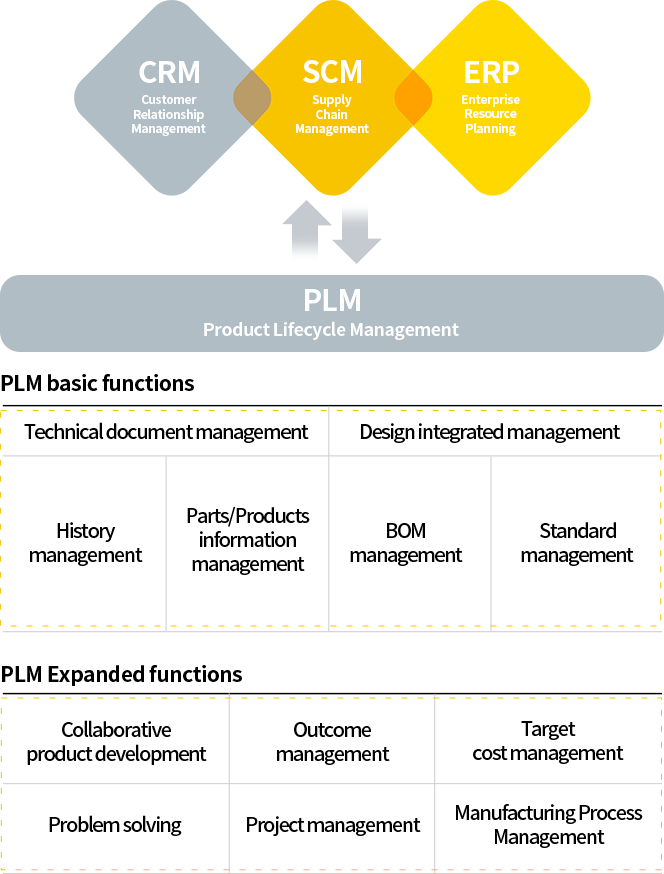

PLM basic functions

PLM has the effect of improving quality, reducing costs, and shortening product development periods, which can maximize profit creation, which is the essential goal of a company.

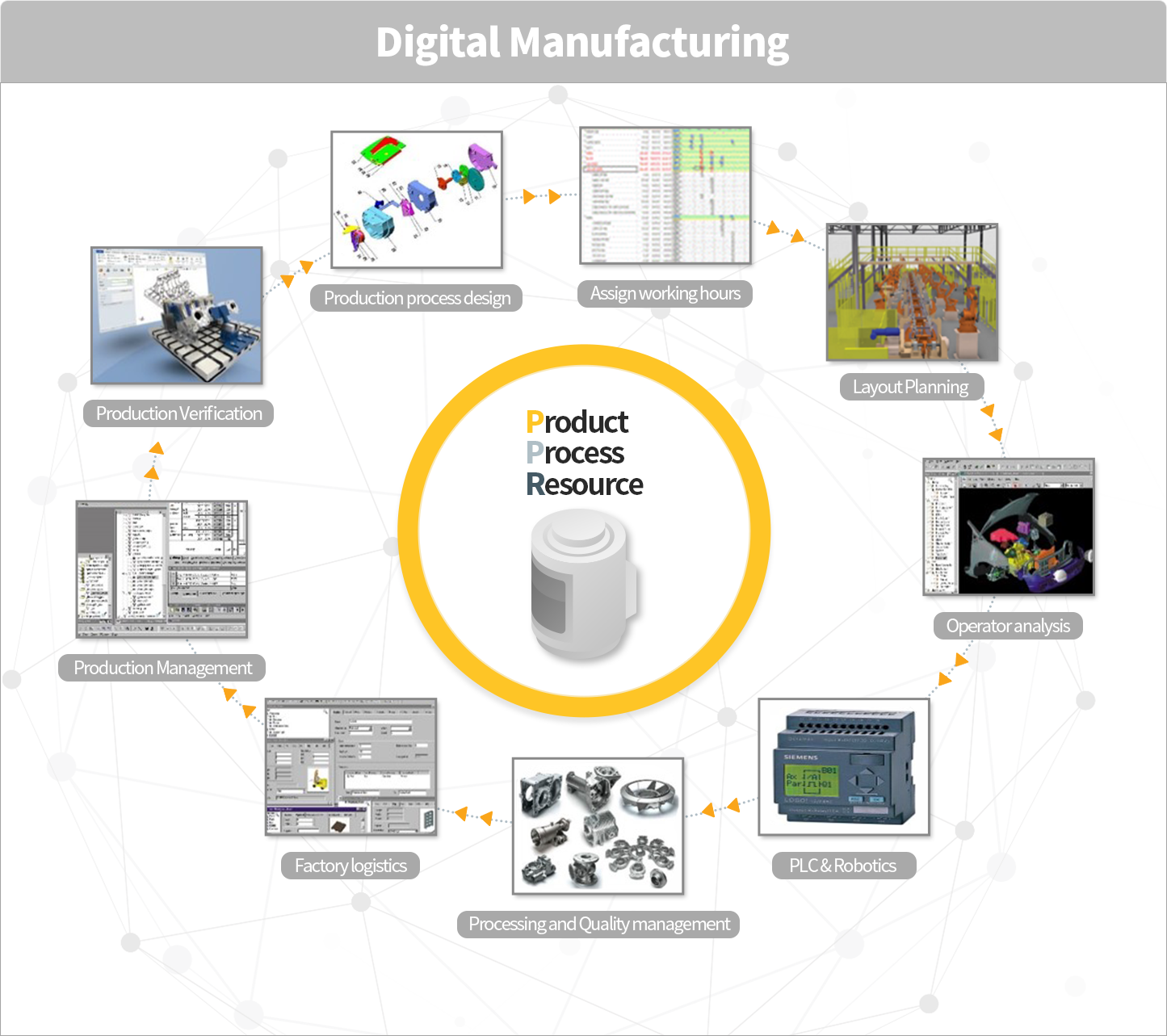

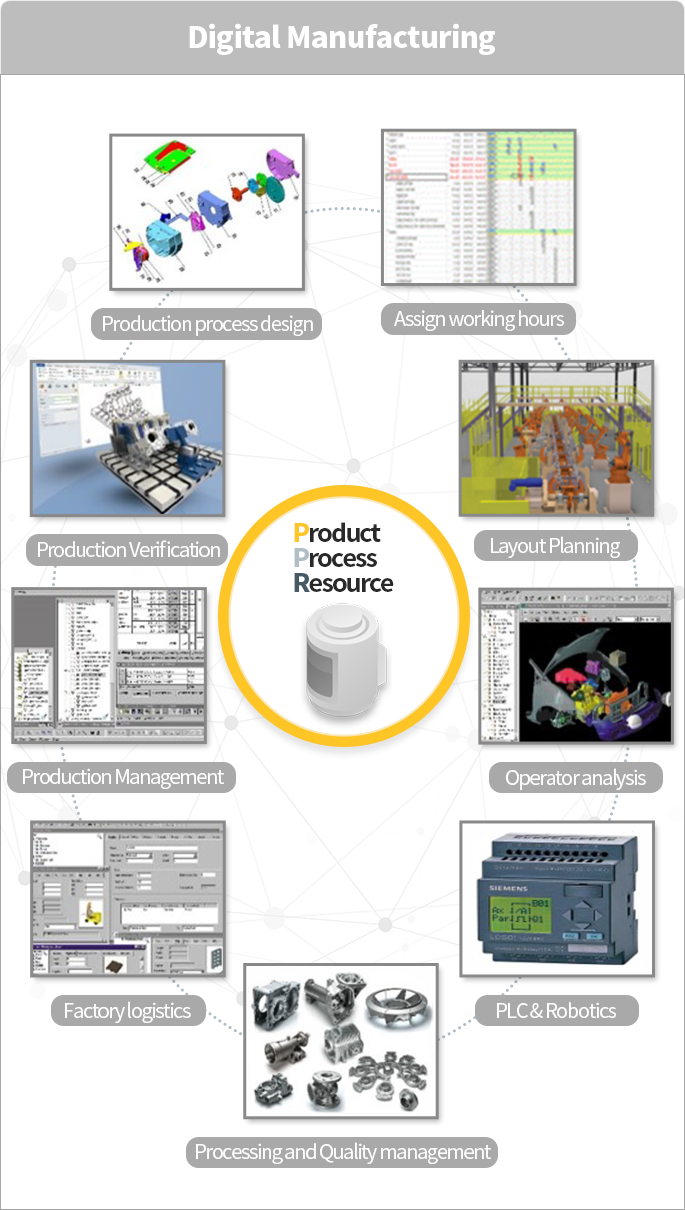

Digital Manufacturing(Tecnomatix)

Before and after product mass production, this enables review,

planning, and verification of products, facilities and production

methods in a virtual digital environment.

planning, and verification of products, facilities and production

methods in a virtual digital environment.

DM(Tecnomatix)

Before and after product mass production,

this enables review, planning, and verification of products, facilities and production methods

in a virtual digital environment.

this enables review, planning, and verification of products, facilities and production methods

in a virtual digital environment.

Simulation, visualization and optimization of production systems

and logistics processes can reduce market time, manage complexity,

improve productivity, and increase reuse and reduce costs.

and logistics processes can reduce market time, manage complexity,

improve productivity, and increase reuse and reduce costs.

Simulation, visualization and optimization of

production systems and logistics processes can

reduce market time, manage complexity, improve

productivity, and increase reuse and reduce costs.

production systems and logistics processes can

reduce market time, manage complexity, improve

productivity, and increase reuse and reduce costs.

| Time saving |

| Cost saving(Direct cost, Indirect cost, investment etc) |

| Productivity improvement |

| Physical assembly quality improvement |

| Collaboration and communication improvement |

| Build information-saving Hub |

| Logistics improvement and effciency of space utilization |

| Work environment improvement and workload reduction |

| Increasing maintenance efficiency |

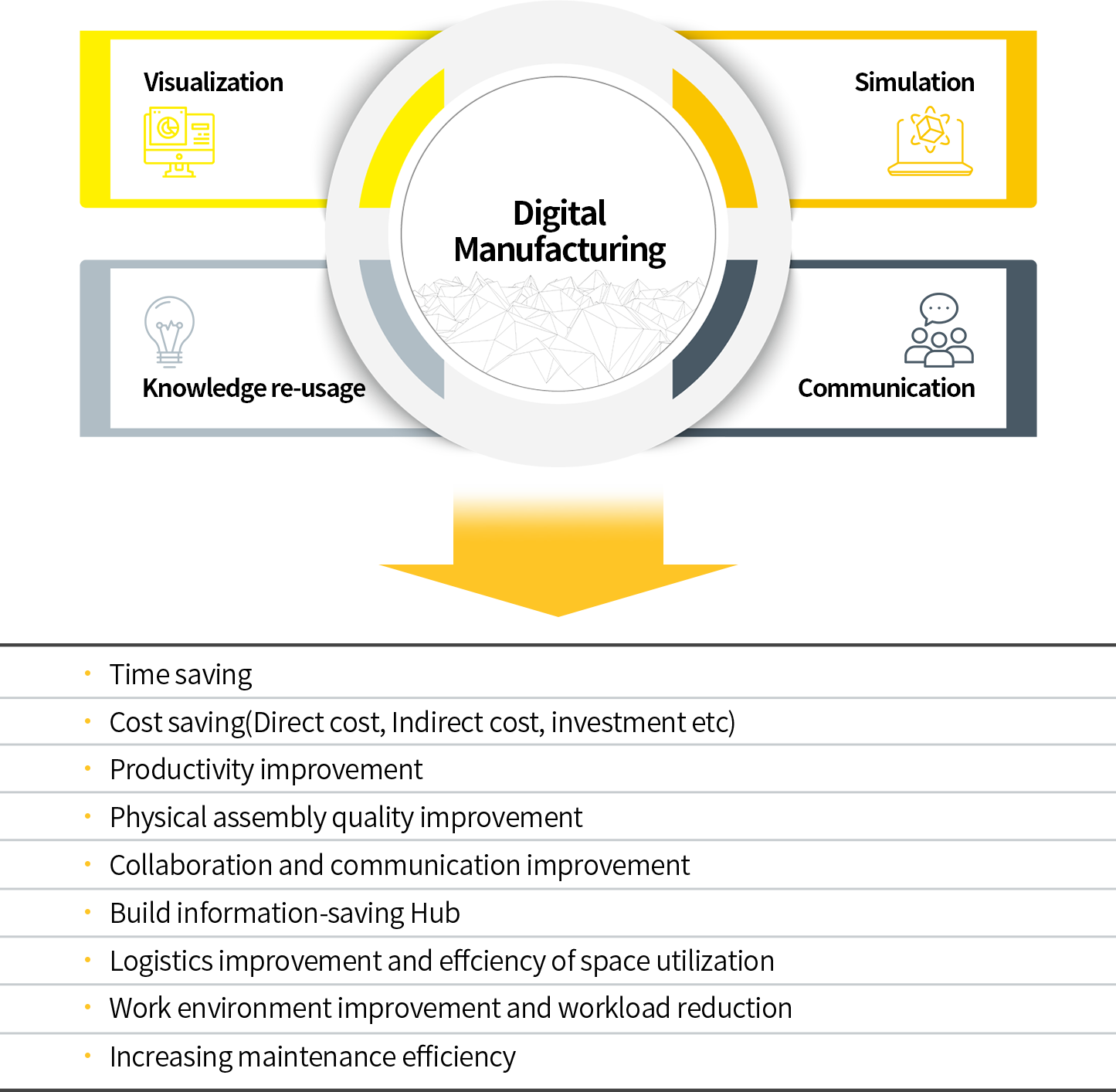

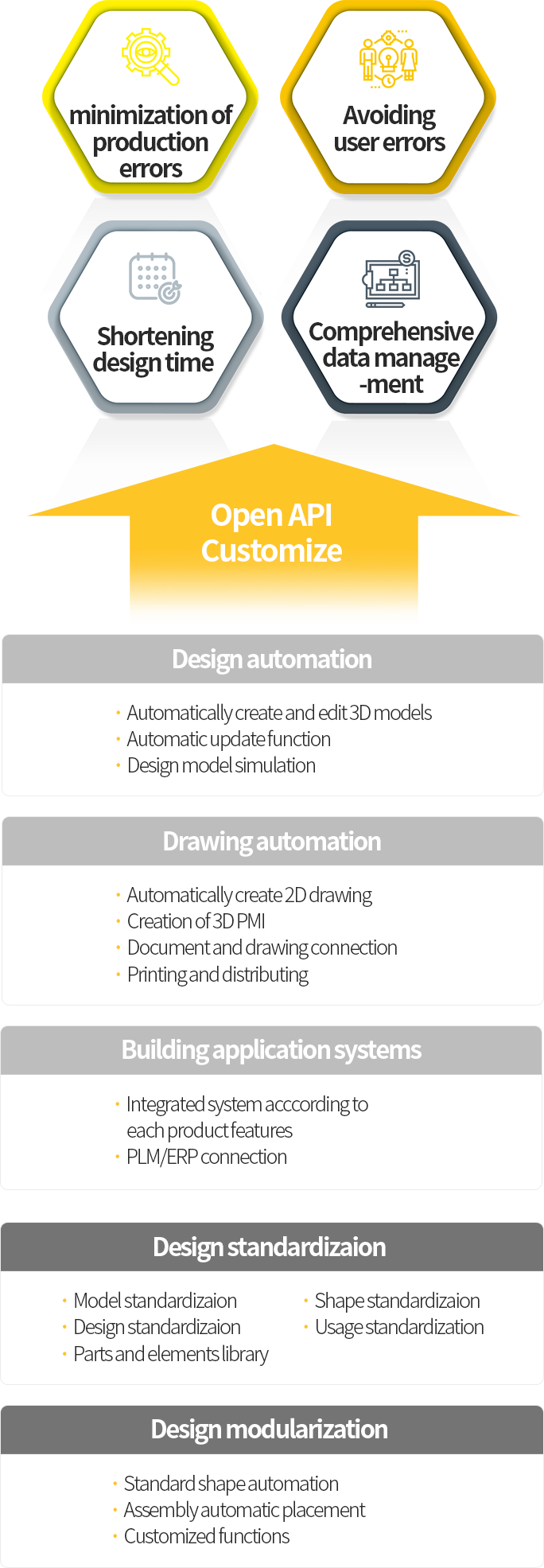

3D CAD (NX)

From design standardization to application system construction,

3D CAD Customize using NX Open API customization from design

standardization to application system improves design quality and

product development speed and gives business a competitive edge.

3D CAD Customize using NX Open API customization from design

standardization to application system improves design quality and

product development speed and gives business a competitive edge.

From design standardization to application system

construction, 3D CAD Customize using NX Open API

customization from design standardization to

application system improves design quality and

product development speed and gives business

a competitive edge and workers.

construction, 3D CAD Customize using NX Open API

customization from design standardization to

application system improves design quality and

product development speed and gives business

a competitive edge and workers.

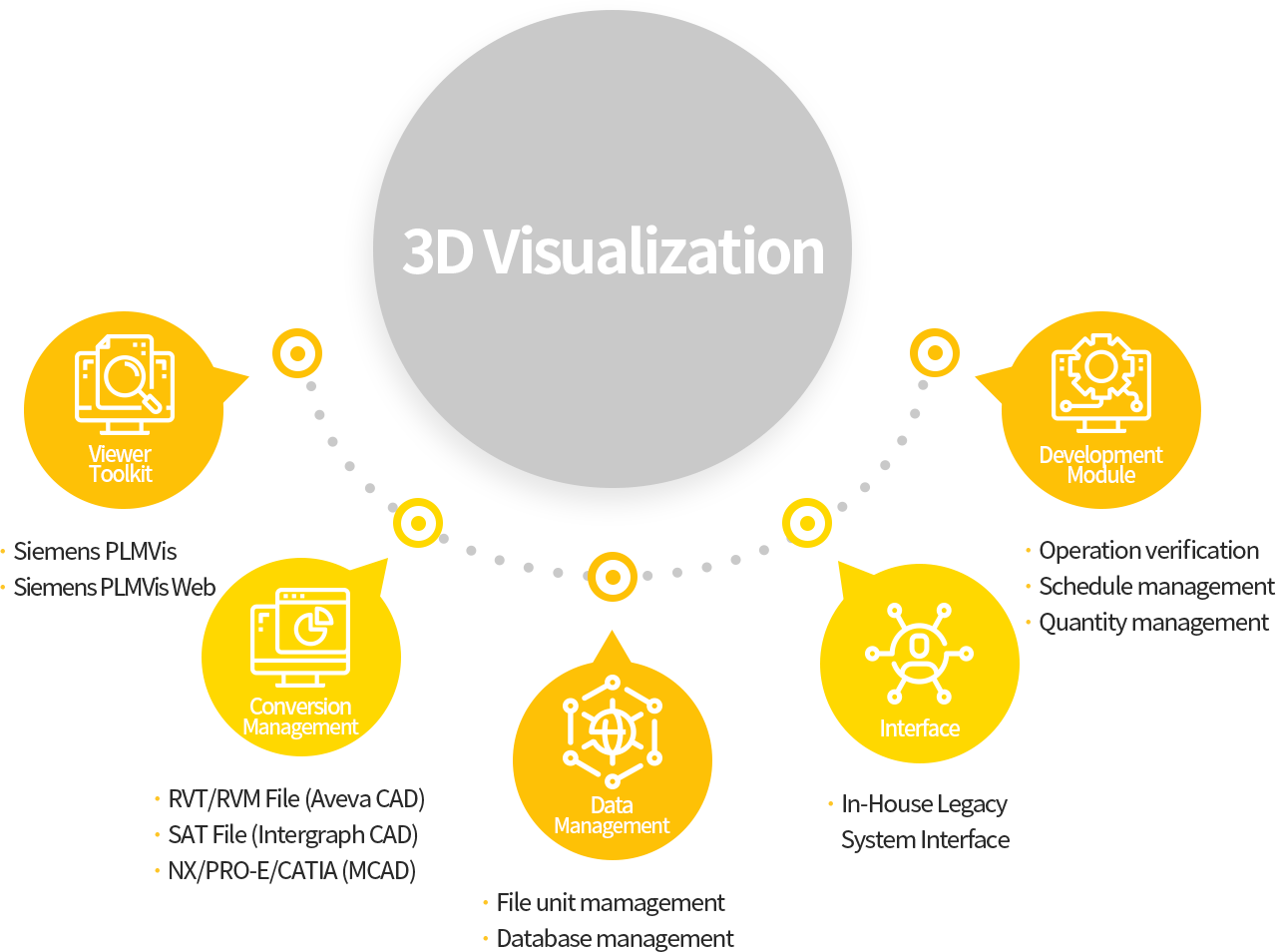

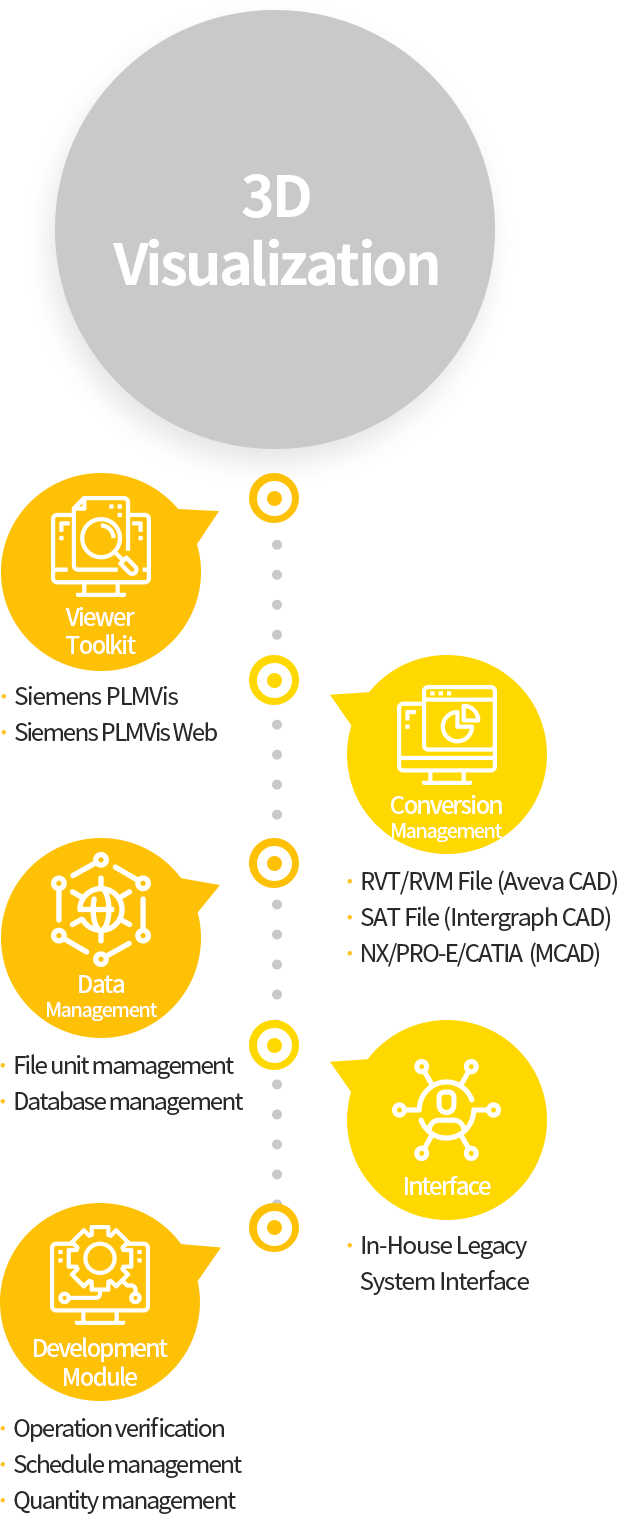

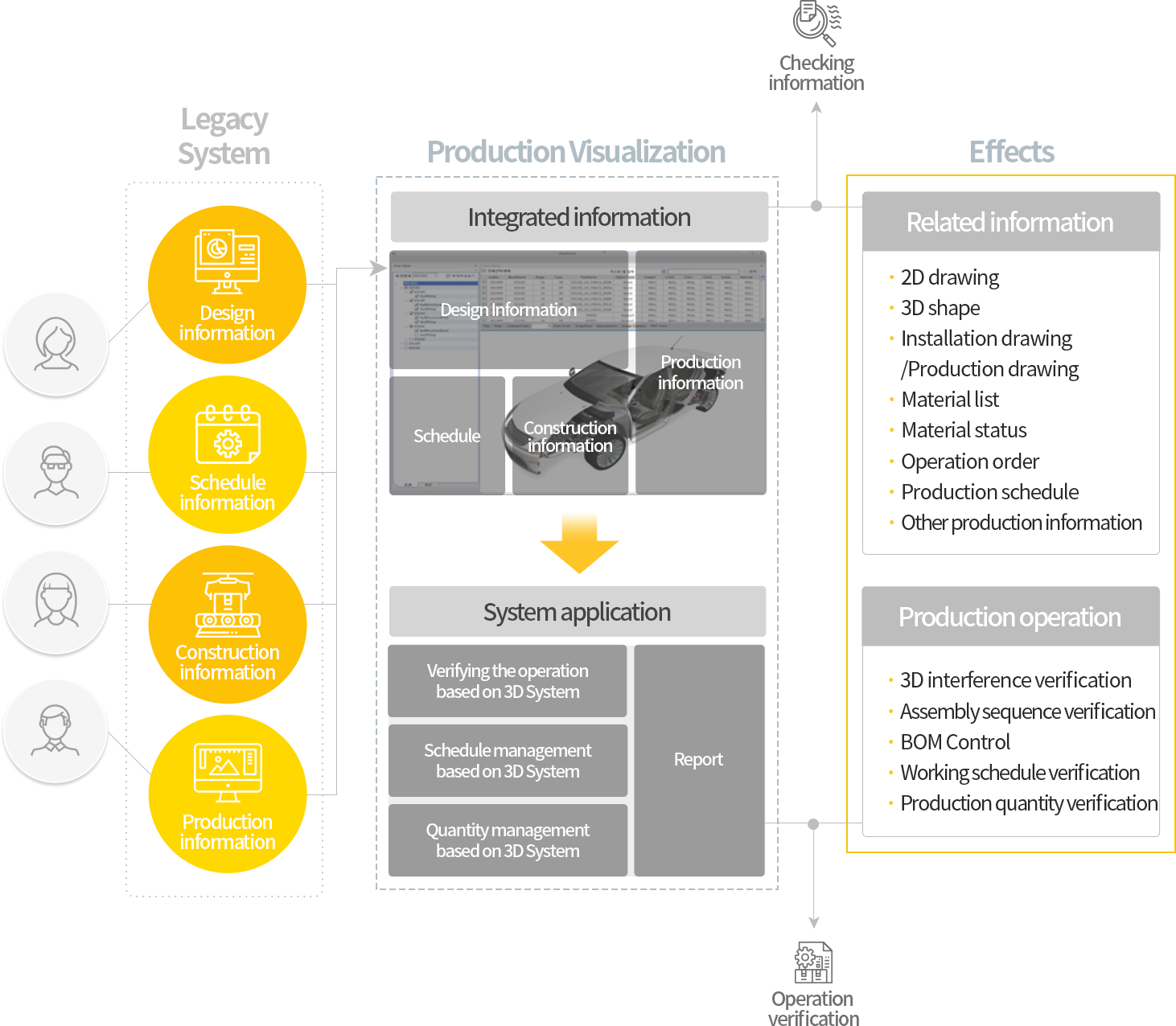

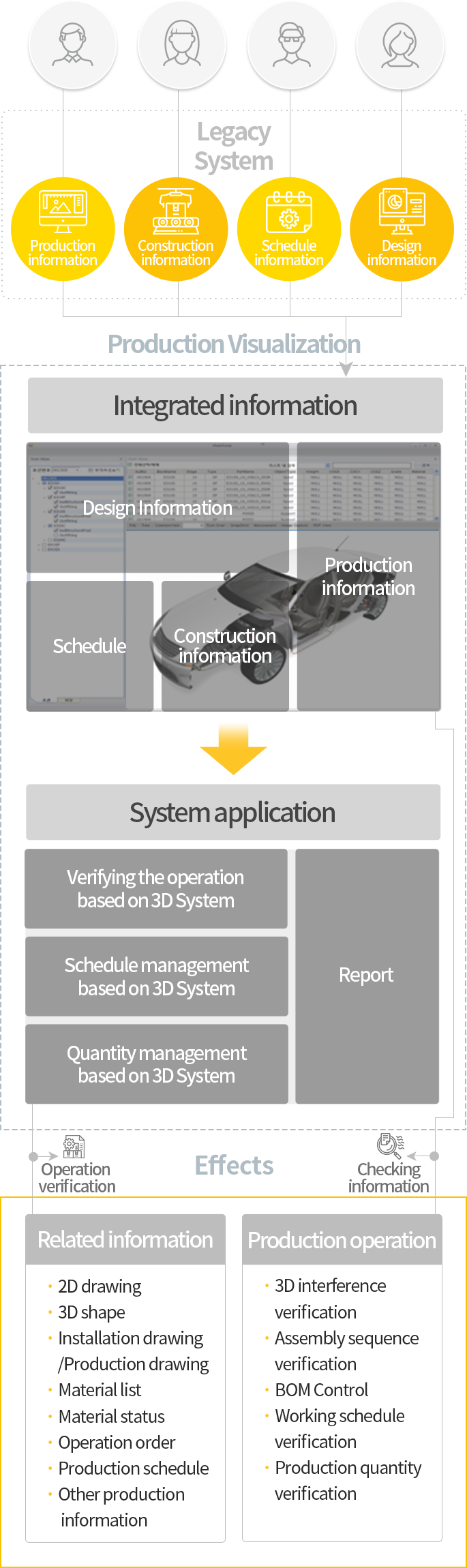

3D Visualization

Production efficiency can be improved through visualization system

since 3D visualizaiton provides integrated Legacy System information

such as 2D/3D designs, schedules, productions, construction to users

and workers.

since 3D visualizaiton provides integrated Legacy System information

such as 2D/3D designs, schedules, productions, construction to users

and workers.

Production efficiency can be improved through

visualization system since 3D visualizaiton provides

integrated Legacy System information such as

2D/3D designs, schedules, productions, construction

to users and workers.

visualization system since 3D visualizaiton provides

integrated Legacy System information such as

2D/3D designs, schedules, productions, construction

to users and workers.

3D Visualization Configuration

Visualization System

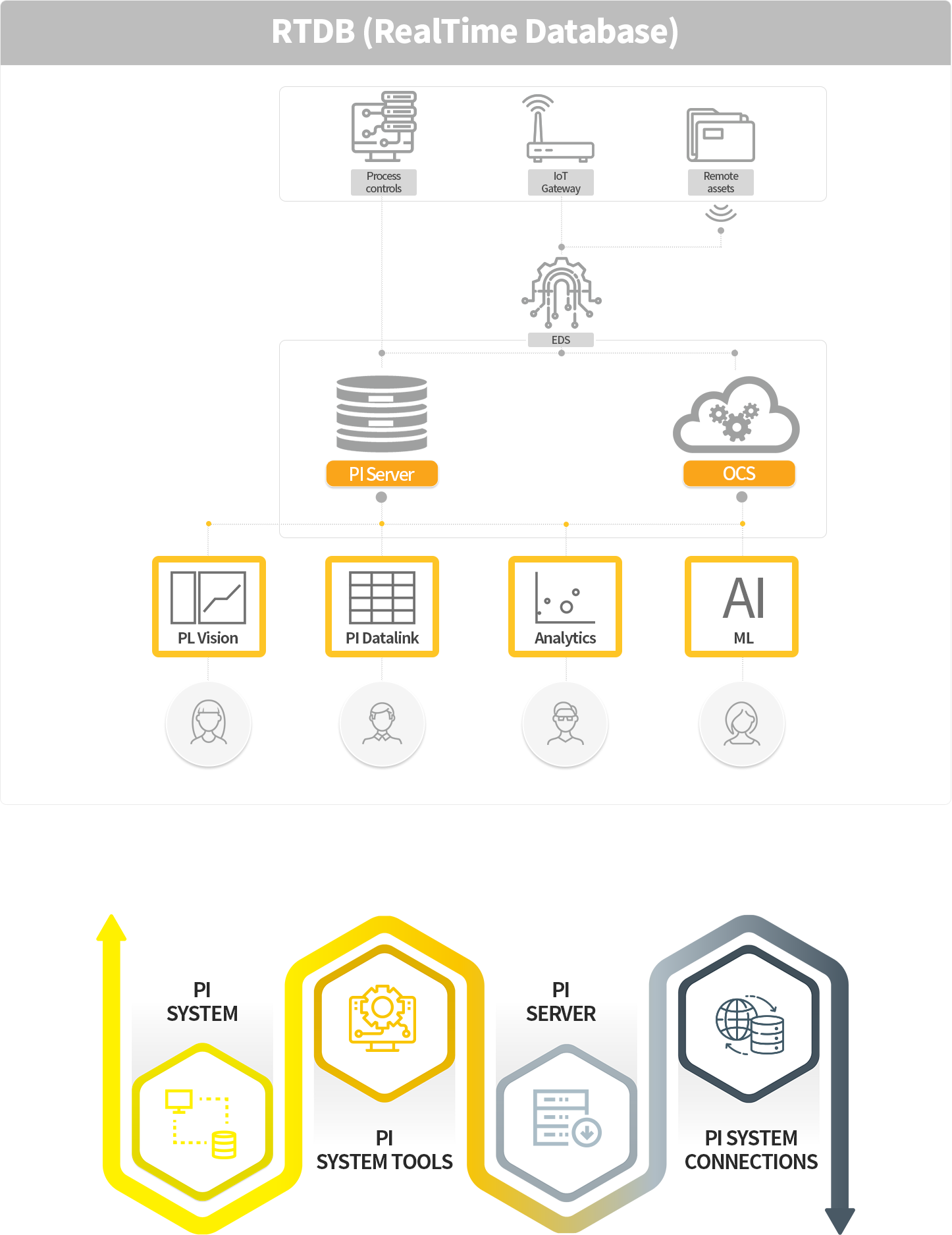

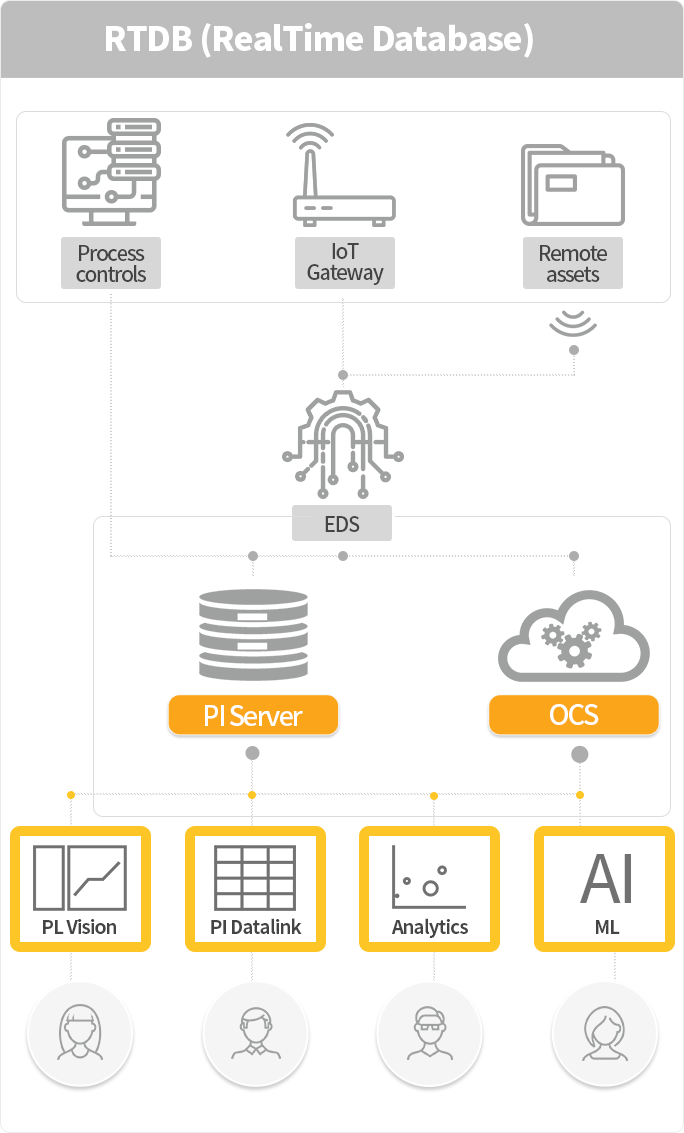

RTDB

RTDB(RealTime Database) is widely used in various fields such as

manufacturing, public works, life science and process industry.

RTDB helps customer asset management, risk mitigation, regulatory

compliance, process improvement, real-time business decisions, and

enables business and market opportunities to be obtained.

RTDB collects, stores, and manages process data from DCS or PLC based on OIS.

manufacturing, public works, life science and process industry.

RTDB helps customer asset management, risk mitigation, regulatory

compliance, process improvement, real-time business decisions, and

enables business and market opportunities to be obtained.

RTDB collects, stores, and manages process data from DCS or PLC based on OIS.

RTDB(RealTime Database) is widely used in

various fields such as manufacturing, public works,

life science and process industry.

RTDB helps customer asset management,

risk mitigation, regulatory compliance, process improvement, real-time business decisions, and

enables business and market opportunities to be obtained.

RTDB collects, stores, and manages process data from DCS or PLC based on OIS.

various fields such as manufacturing, public works,

life science and process industry.

RTDB helps customer asset management,

risk mitigation, regulatory compliance, process improvement, real-time business decisions, and

enables business and market opportunities to be obtained.

RTDB collects, stores, and manages process data from DCS or PLC based on OIS.

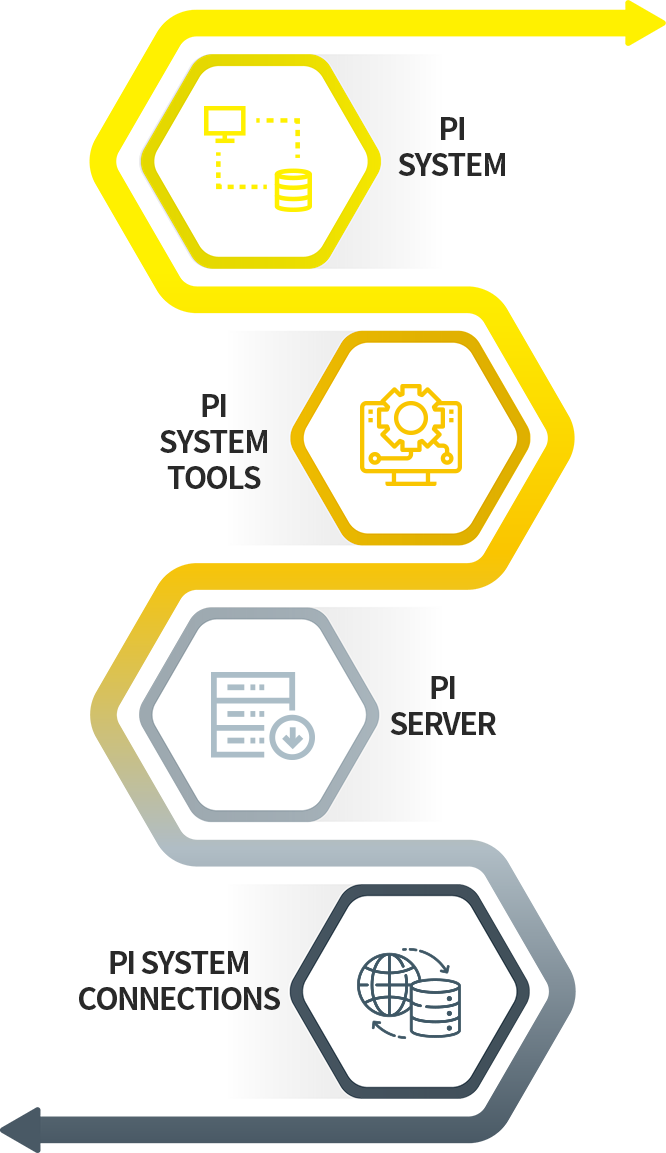

PI System

The OSIsoft PI System served as a reliable,

safe and fast history of collecting industrial equipment data.

Now, OSIsoft PI System discovers operational insights and

new possibilities and enables digital transformation with reliable,

high-quality operational data.

safe and fast history of collecting industrial equipment data.

Now, OSIsoft PI System discovers operational insights and

new possibilities and enables digital transformation with reliable,

high-quality operational data.

The OSIsoft PI System served as a reliable, safe and

fast history of collecting industrial equipment data.

Now, OSIsoft PI System discovers operational insights and new possibilities and enables digital transformation with reliable, high-quality operational data.

fast history of collecting industrial equipment data.

Now, OSIsoft PI System discovers operational insights and new possibilities and enables digital transformation with reliable, high-quality operational data.